TASK 16 : Datasheets Report Writing

Objective:

Study the datasheet of L293D motor driver and write a report on it. Specify about the ICs used in it, PWM, H-bridge etc.

REPORT ON L293D MOTOR

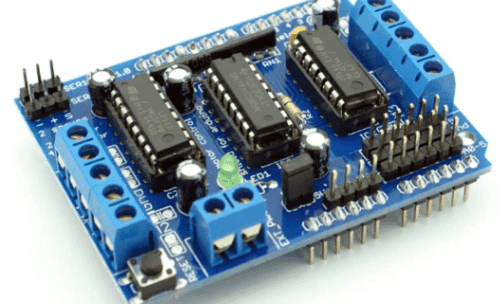

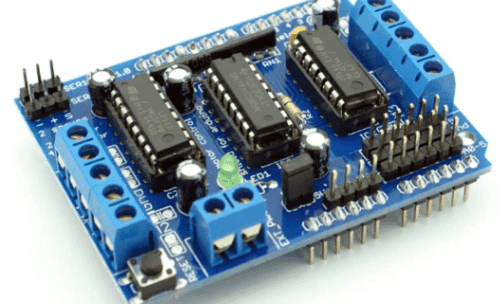

L293D is a basic motor driver, which enables us to drive a DC motor in either direction and also control the speed of the motor. It consists of an inbuilt dual H-bridge circuit. It is thus capable of controlling 2 DC motors at a time. There are 2 OUTPUT pins, 2 INPUT pins, and 1 ENABLE pin for driving each motor. It is designed to drive inductive loads such as solenoids, relays, DC motors, and bipolar stepper motors as well as other high-current/high-voltage loads. The IC has 16 pins (i.e. 8 pins on each side) and also includes built-in kick-back diodes to prevent damage when the motor is de-energized.

(TECHNICAL SPECIFICATIONS)

(L293D Pins)

- There are a total of 4 ground pins in L293D IC because it has to deal with heavy currents.

| PIN No. | Name | Function |

|---|---|---|

| 1 | EN A | When this pin is given HIGH or Logic 1, the left side of the IC works and when it is low, the left side doesn’t work |

| 2 | IN 1 | When this pin is given HIGH or logic 1, the output 1 becomes HIGH |

| 3 | OUT 1 | This pin is connected to one of the terminals of motor 1 |

| 4,5 | GND | Should be connected to the circuit’s ground |

| 6 | OUT 2 | This pin is connected to the other terminal of motor 1 |

| 7 | IN 2 | When this pin is given HIGH or Logic 1, the output 2 becomes HIGH |

| 8 | VCC 2 | This is the voltage required to run the motor. It can be greater than the IC voltage (VCC 1) |

| 16 | VCC 1 | It provides power to the l293D IC. So, this pin should be supplied with 5 V |

| 15 | IN 4 | When this pin is given HIGH or logic 1, the output 4 becomes HIGH |

| 14 | OUT 4 | This pin is connected to one of the terminals of motor 2 |

| 13,12 | GND | Should be connected to the circuit’s ground. |

| 11 | OUT 3 | This pin is connected to the other terminals of motor 2. |

| 10 | IN 3 | When this pin is given HIGH or logic 1, the output 3 becomes HIGH |

| 9 | EN B | When this pin is given HIGH or Logic 1, the right side of the IC works and when it is low, the right side doesn’t work |

* PWM : to control the speed of the DC motor The speed of a DC motor can be controlled by changing its input voltage. A widely used technique to accomplish this is Pulse Width Modulation (PWM). PWM is a technique in which the average value of the input voltage is adjusted by sending a series of ON-OFF pulses. This average voltage is proportional to the width of the pulses, which is referred to as Duty Cycle.

- H-Bridge : to control the spinning direction of the DC motor The spinning direction of a DC motor can be controlled by changing the polarity of its input voltage. A common technique for doing this is to use an H-bridge. An H-bridge circuit consists of four switches with the motor in the center forming an H-like arrangement. Closing two specific switches at a time reverses the polarity of the voltage applied to the motor, which causes a change in the spinning direction of the motor.