BLOG · 11/2/2024

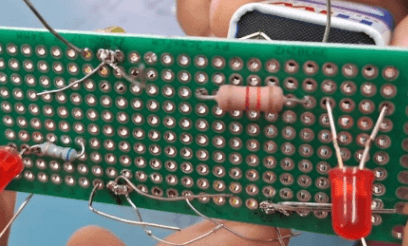

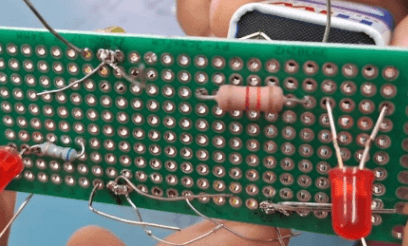

TASK 12 : Soldering Prerequisites\nSoldering Equipment:\nSoldering Iron: This handheld tool provides the heat source needed to melt the solder. Soldering irons are typically pencil-like in shape and consist of several different parts that work together to form a comfortable, practical and easy-to-use tool.\n\nSolder Flux: Solder flux is a purifying agent. Flux serves three different purposes simultaneously. First, it purifies the components you're soldering by cleaning them of any rust. It also closes out any extra air that might come into contact with the material, thus preventing future rust. Finally, it improves the dripping individuality of the solder itself.\n\nPerf Board: Perfboards are also called Perforated Circuit Boards, Prototyping Boards, and Dot PCBs. It's basically a bunch of copper pads on circuit board material, usually on one side but the copper pads can be on both sides.\n\nHelping Hands: A helping hand is generally a stand with flexible clamps that hold objects in place which leaves you hands free to carry on with your work.\n\nPrecision Tweezers: Anti-magnetic stainless steel general-purpose tweezers offer precision tip symmetry and balance with good corrosion resistance to most chemicals and acids.\n\nSolder: Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling.\n\nThe Soldering Process\nStep 1: If the perf board is full, desolder it by using a desoldering wick.\n\nStep 2: Place the perf board on the helping hand for better precision.\n\nStep 3: Place the required LED on to the perf board, on a side without copper pads.\n\nStep 4: Bend the leads to follow the path you want them to have. Add a bit of solder to both ends of that lead to hold it in place.\n\n